Exploring 3D-Printed Coffee Makers: A Glimpse into the Future

Table of Contents

- The Evolution of Coffee Makers

- What is a 3D-Printed Coffee Maker?

- How 3D Printing is Changing Coffee Brewing

- 1. Customization and Personalization

- 2. Cost-Efficient Manufacturing

- 3. Sustainability and Waste Reduction

- 4. Rapid Prototyping and Innovation

- 5. Open-Source Coffee Maker Designs

- Examples of 3D-Printed Coffee Makers

- ☕ 1. OpenPress Espresso

- ☕ 2. Pour-Over Coffee Stands

- ☕ 3. Smart Coffee Dispensers

- ☕ 4. Coffee Bean Grinders

- Challenges and Limitations of 3D-Printed Coffee Makers

- The Future of 3D-Printed Coffee Makers

- Final Thoughts

Exploring 3D-Printed Coffee Makers: A Glimpse into the Future

- azeem memon

- 31-01-2025

- 23-07-2025

- 3486 views

- Coffee Shop

Innovation in coffee brewing technology has come a long way, and the introduction of 3D printing is pushing the boundaries of how coffee makers are designed and manufactured. With the rise of customization, sustainability, and cost-effective production, 3D-printed coffee makers are shaping the future of home and commercial coffee brewing.

In this blog, we will explore what 3D-printed coffee makers are, how they work, their benefits, challenges, and what the future holds for this cutting-edge technology.

The Evolution of Coffee Makers

Coffee brewing has evolved from simple boiling methods to advanced espresso machines, drip brewers, and smart coffee makers. However, traditional manufacturing often involves high costs, mass production limitations, and material waste.

This is where 3D printing enters the picture, allowing for greater flexibility, efficiency, and personalization in coffee maker designs.

What is a 3D-Printed Coffee Maker?

A 3D-printed coffee maker is a brewing device created using additive manufacturing (3D printing) instead of traditional production techniques like molding or metal fabrication. These coffee makers can range from simple pour-over stands to fully functional espresso machines, all made with custom-designed, printed components.

3D printing uses materials such as:

🔹 Plastic filaments – For lightweight, cost-effective parts.

🔹 Metal powders – For durability and heat-resistant parts.

🔹 Food-safe resins – Ensuring safety for coffee consumption.

How 3D Printing is Changing Coffee Brewing

1. Customization and Personalization

With 3D printing, coffee lovers can create unique coffee maker designs suited to their exact preferences. Whether it’s a personalized pour-over stand, an espresso tamper, or a new brewing mechanism, users can tailor their devices for a one-of-a-kind experience.

2. Cost-Efficient Manufacturing

Traditional coffee machine manufacturing involves expensive tooling and mass production. 3D printing significantly reduces costs by eliminating the need for molds and assembly lines, making it ideal for small businesses and home enthusiasts.

3. Sustainability and Waste Reduction

3D-printed coffee makers are often made from recycled or biodegradable materials, reducing the environmental impact of coffee machine production. Additionally, on-demand printing minimizes waste by only producing what is needed.

4. Rapid Prototyping and Innovation

Companies and independent creators can test new coffee brewing concepts quickly and affordably. This leads to faster innovation cycles, where new designs can be adjusted and improved before full-scale production.

5. Open-Source Coffee Maker Designs

Many 3D printing communities share open-source coffee maker designs, allowing anyone with a 3D printer to download and print their own brewing device at home.

Examples of 3D-Printed Coffee Makers

☕ 1. OpenPress Espresso

A fully functional 3D-printed espresso machine, designed with sustainable materials and a simple lever mechanism for brewing high-quality espresso.

☕ 2. Pour-Over Coffee Stands

Many enthusiasts print customized pour-over stands with unique shapes and adjustable heights, enhancing the coffee brewing process.

☕ 3. Smart Coffee Dispensers

Engineers have experimented with 3D-printed coffee dispensers that integrate with IoT devices, allowing users to control brewing remotely.

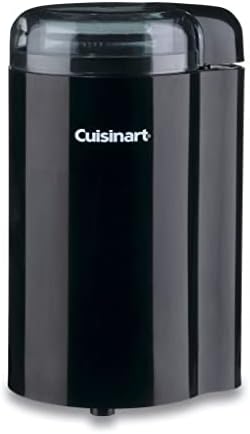

☕ 4. Coffee Bean Grinders

Some creators have even designed 3D-printed coffee grinders, offering adjustable grind settings for precision brewing.

Challenges and Limitations of 3D-Printed Coffee Makers

While 3D-printed coffee makers offer many advantages, there are still some challenges to consider:

🔸 Material Safety – Not all 3D printing materials are food-safe or heat-resistant. It’s crucial to use certified food-grade materials.

🔸 Durability – Plastic-printed parts may not withstand high temperatures or prolonged use like traditional metal coffee machines.

🔸 Complexity of Assembly – Some 3D-printed designs require additional non-printed components, like heating elements or pumps.

🔸 Limited Mass Production – While great for prototyping, 3D printing may not yet replace large-scale manufacturing for commercial coffee makers.

The Future of 3D-Printed Coffee Makers

As 3D printing technology advances, we can expect:

✅ More food-safe and heat-resistant materials for better durability.

✅ Integration with smart technology, allowing for AI-controlled brewing.

✅ Affordable, on-demand printing services, making custom coffee makers accessible to everyone.

✅ Eco-friendly materials, further reducing waste and carbon footprints.

With continued innovation and experimentation, 3D-printed coffee makers may become a mainstream alternative to traditional coffee machines, offering personalized, sustainable, and futuristic brewing solutions.

Final Thoughts

3D printing is revolutionizing the coffee industry, offering endless possibilities for customization, sustainability, and cost-efficient manufacturing. Whether you’re an engineer, a coffee lover, or an entrepreneur, 3D-printed coffee makers present an exciting glimpse into the future of coffee technology.

Would you try a 3D-printed coffee maker? Let us know in the comments!